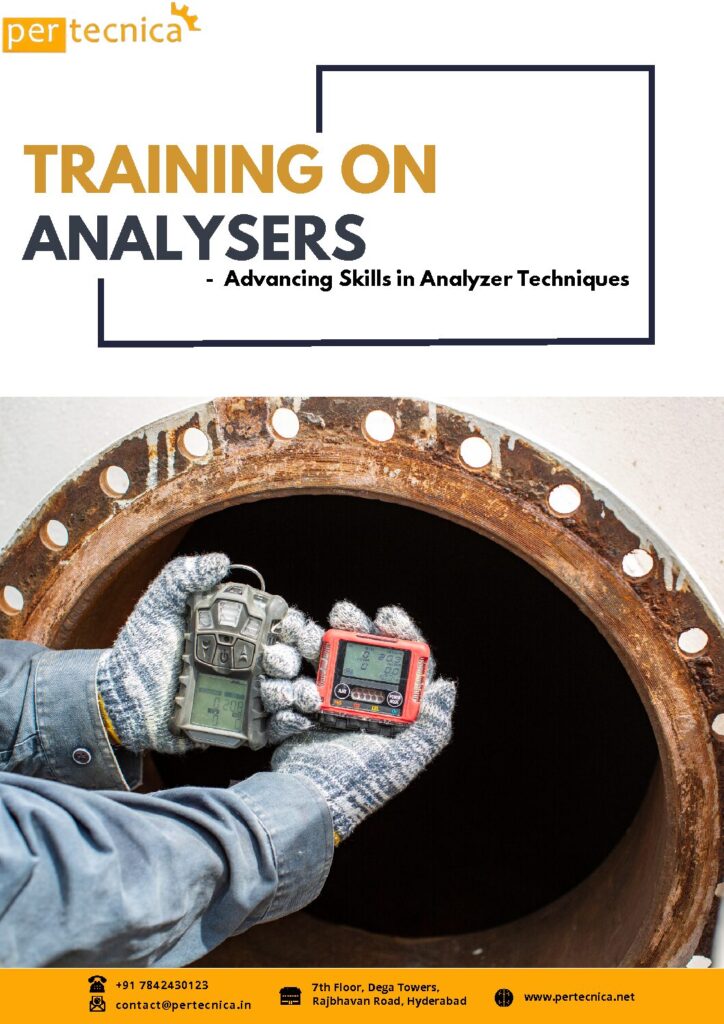

Pertecnica Engineering is one of the best employee training institutes in India on Analyzers Training. Our Analyzers Training Course tailored for employees particularly working in Chemical industries and other industries which require Laboratory analyzing skills. This course delves into the practical aspects of operating various types of analyzers, including gas, chemical, and environmental analyzers. Designed for both beginners and experienced professionals, our training encompasses key areas like analyzer calibration, maintenance, troubleshooting, and safety protocols.

Whether it’s a laboratory setting or an industrial environment, our expert-led sessions provide hands-on experience and in-depth understanding of analytical techniques and instrumentation. Enhance your skills in data interpretation, quality control, and efficient operation of analytical equipment. Join our course to elevate your proficiency in using advanced analyzer technology and become a valuable asset to your organization with top-notch analytical skills