Pertecnica Engineering leads the way as India’s top training institute for welding. Our specialized programs offer comprehensive expertise and practical skills needed to master welding techniques.

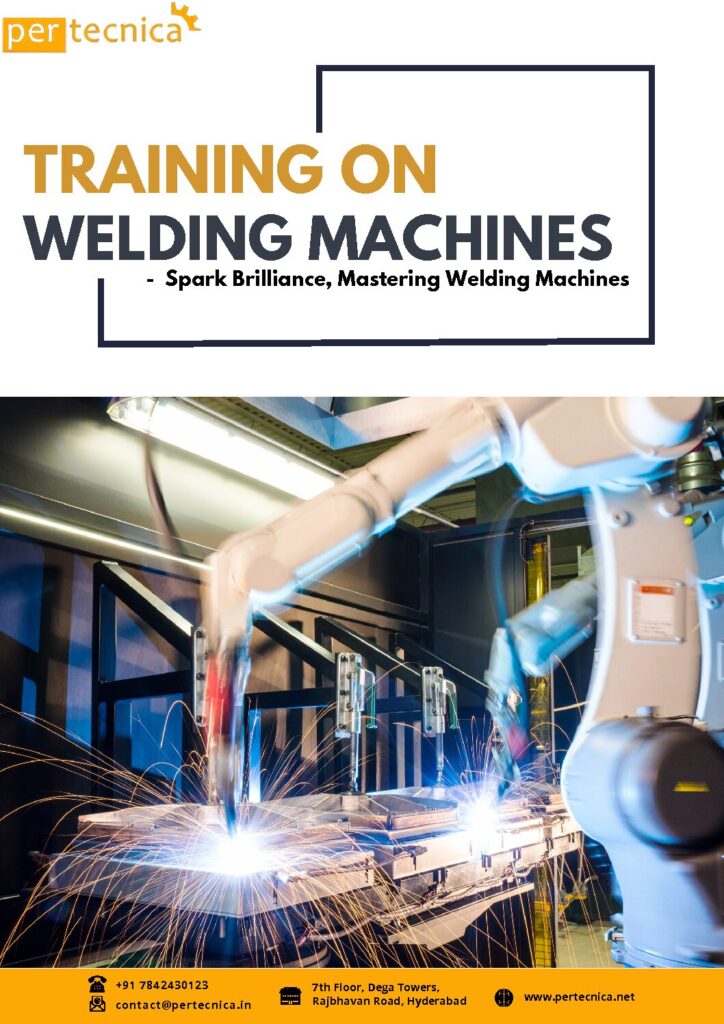

Embark on a transformative learning journey with our comprehensive Training on Welding Technologies, designed to cater to employees across various industries. This course offers a deep dive into the world of welding, covering a wide range of techniques and applications. Whether you’re a beginner or looking to enhance your existing skills, this training is perfect for anyone interested in mastering the art and science of welding.

Our expert instructors will guide you through various methods such as MIG, TIG, and stick welding, along with cutting-edge welding technologies and safety protocols. You’ll gain practical, hands-on experience in metal joining, fabrication, and repair techniques, ensuring you leave the course with a robust understanding of welding principles and practices. Ideal for manufacturing technicians, engineers, and artisans, our training is your gateway to becoming a proficient welding professional, equipped to tackle diverse challenges in the modern industrial landscape